REVIEW

CIDPEX Review

CIDPEX2025 Machinery and Equipment Pavilion

By Zhang Yuan, Qi Xiaohua, Ge Jiming, Zhang Shengyou, Guo KaiyuanI. Tissue Machine and Fittings Pavilion

Shandong Hicredit Heavy Machinery Co., Ltd.

HC Series Crescent Former High-Speed Tissue Machine

Headbox Formation Diffuser: Improved design enhances the slurry discharge speed at the lip, optimizes fiber alignment, reduces the proportion of long fiber usage by 5%–10%, and improves the bulk and formation of tissue.

Steam Condensate and Hot Air System: Improves exhaust gas and condensate recovery efficiency, reducing steam consumption by 5%.

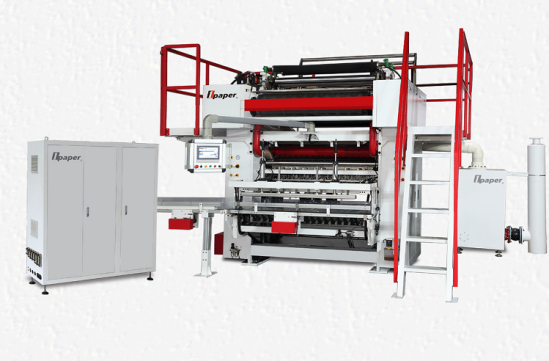

Shandong Xinhe Paper-making Engineering Co., Ltd.

Independent Shoe Press Tissue Machine: With a width of 5,600 mm, it uses dual-felt independent shoe press technology, improving dewatering efficiency by over 20% and reducing energy consumption.It uses soft shoe press technology, boosting machine speed by more than 15% to reach up to 1,600 m/min. The high linear pressure Yankee Cylinder technology increases bulk by over 10%.

Wide-Wire Fourdrinier Multi-Cylinder Hand Towel Machine: With a width of 5,600 mm, the design speed can reach 800 m/min.

Shanghai Qingliang Industry Co., Ltd.

Crescent Former Tissue Machine: Utilizes permanent magnet direct drive motors and booster pumps, saving 10%–15% of energy. The fully cantilevered design of the machine facilitates easier replacement of forming fabrics and felts.

ANDRITZ (China) Ltd.

PrimeLineHyTAD Tissue Machine: Through process optimizations, the machine’s energy consumption is reduced to half that of a TAD system, while product quality reaches about 90% of the performance of TAD products.

Jiangsu Jinni Engineered Fabric Co., Ltd.

Forming Fabrics: Improved weaving process of the base material increases fiber and additive retention by 3%–5%, extends service life by 20%–25%, and delivers good paper quality. It can be used to produce tissue parent rolls with a basis weight of 10.5 gsm.

II. Energy-Saving Equipment Pavilion

Nanjing CIGU Technology Co., Ltd.

Magnetic Levitation Vacuum Pump: The design uses magnetic levitation bearings and high-power high-speed permanent magnet synchronous motors, enabling contactless, frictionless rotor operation. Operating efficiency is 30% higher than traditional water ring vacuum pumps, saving over 40% of energy. Oil-free operation averts the risk of lubricant contamination. Lower noise and easier maintenance.

Shandong Zhangqiu Blower Co., Ltd.

Magnetic Levitation Blower: The design uses magnetic levitation bearings, ternary flow impellers, and permanent magnet synchronous motors. Features an integrated skid-mounted structure, one-button start/stop, and low noise.

Multi-Stage Centrifugal Vacuum Pump: Can be customized; automatically adjusts speed via frequency conversion based on the tissue machine production speed, reducing energy consumption.

Shanggu Turbo Machinery (Qidong) Co., Ltd.

Turbine Vacuum Pump: Combines permanent magnet direct drive motors with inverter speed control systems, saving over 50% of energy compared to water ring vacuum pumps.

III. Converting Machinery for Tissue Products Pavilion

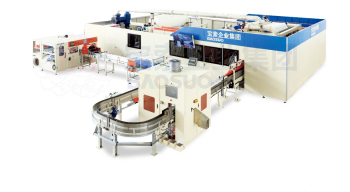

Baosuo Group

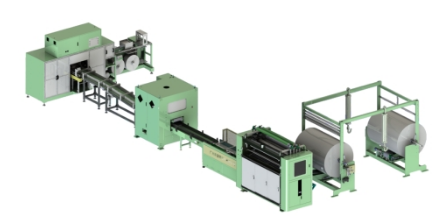

Ultra-Wide, High-Speed N-Fold Bottom-Up Kitchen Towel/Hand Towel Production Line: Uses a central suction principle for more uniform paper adsorption and a flat, stable paper surface. Width: 2,900–3,700 mm; Speed: 150–180 m/min. The wide-width design allows tissue parent rolls to be slit directly without rewinding, reducing losses during the rewinding process. The N-fold design improves water absorbency and bulk. Suitable for producing both regular and bottom-up kitchen towels/hand towels.

IE5+ Slotless Direct Drive Servo Smart Workstation: Integrates an AI diagnostic system to prevent failures, effectively reducing power consumption and product costs.

24-Hour Intelligent Inspection Robot: Automatically monitors equipment operation and uploads photos to the AI system, reducing labor costs and human operational errors.

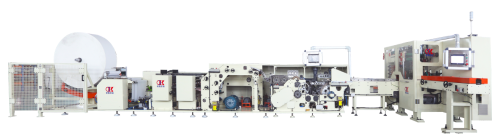

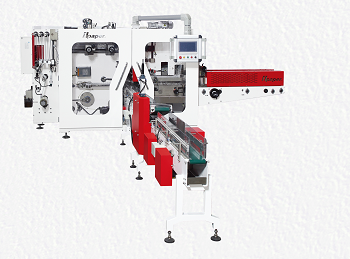

OK Science and Technology Co., Ltd.

Soft Pack Facial Tissue Production Line: Width: 2,800 mm. The large-width folder uses a six-roller design to ensure operational stability; running speed: 200 m/min. The single packer is equipped with an integrated laser coding and laser perforation unit. Laser perforation technology spares the need for tear tapes, saving costs.

Portable Pack Lotion Handkerchief Tissue Production Line: A new packaging format for lotion tissue, using a dual-channel design with a production speed of 180 packs/min.

Collaborative Palletizing Robot: Features high flexibility and precision, capable of adapting to different product specifications and palletizing requirements.

Transport Robot: Capable of precise path planning and intelligent obstacle recognition, ensuring safe and efficient operation.

Soft Pack Facial Tissue Production Line

Portable Pack Lotion Handkerchief Tissue Production Line

Dechangyu Paper Machinery

Adhesive-Free Embossing Technology: Enables adhesive-free embossing for low basis weight products, delivering bulky, soft, smooth, and resilient products.

High-Speed Printing Technology: Available in large-width models of 3,700 mm and 2,900 mm; speed: 400 m/min. Dual-color high-precision registration printing accurately reproduces complex patterns. Easy operation with one-button automatic printing plate cleaning reduces waste rate and downtime.

Guangdong Zhidesheng Technology Co., Ltd.

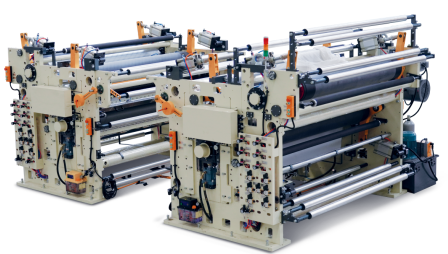

Seven-Roll 3D Embossing Unit: Allows flexible switching of paper paths, achieving "one machine for multiple uses" and reducing investment costs. Compatible with embossing methods like seven-roll single-side lamination and seven-roll double-side point-to-point lamination, meeting diverse needs. Embossing patterns can be customized.

Three-Roll Embossing Unit: Uses a flexible rubber roller design with cushioning and damping effects, reducing impact and noise between rollers. Allows switching between flat embossing and 3D embossing. Convenient adjustment method and stable operation.

Quanzhou Huaxun Machinery Making Co., Ltd.

Lotion Coating and Printing Machine: Lotion coating amount ranges from 5% to 45%, capable of producing lotion paper with different characteristics to meet customer needs.

Lotion Coating and Printing Machine

IV. Tissue Paper Packaging Equipment Pavilion

Shanghai Songchuan Fengguan Packaging Automation Co., Ltd.

WP-20 Collaborative Palletizing Robot: Features multiple palletizing patterns and can autonomously complete tasks such as sorting, handling, and transporting goods. Load capacity: 30–50 kg (including end effector).

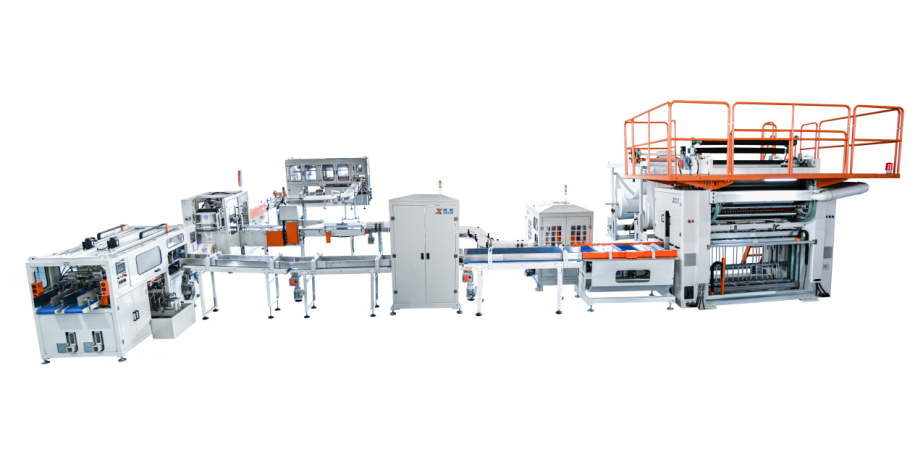

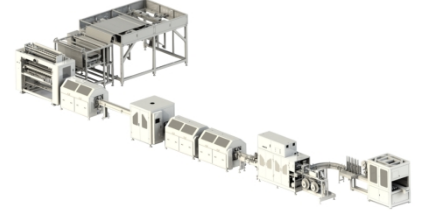

Complete Line Solution for Soft Pack/Bottom-Up/Cotton Soft Towels: The production line covers processes from single packing, multi-packing, cartoning (or bagging) to palletizing. Each section has independent drive control and tension control. Optional units include edge embossing, embossing, and gluing lamination, ensuring smooth and efficient entire line production.

WP-20 Collaborative Palletizing Robot

Complete Line Solution for Soft Pack/Bottom-Up/Cotton Soft Towels

Zhejiang Onepaper Smart Equipment Co., Ltd.

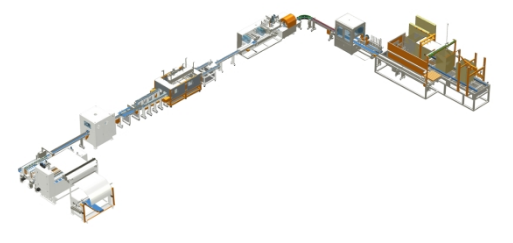

Point-to-Point Four-Edge Embossed Pop-Up Facial Tissue Production Line: Uses four-edge embossing technology to achieve precise alignment. The first sheet employs an inward-fold lock paper technology, enhancing the user experience by making the first sheet easier to pull out after opening the pack, avoiding tearing issues. The entire line integrates embossing, folding, cutting, and packaging, with speeds of up to 130 m/min.

High-Speed Soft Pack Tissue Packaging Machine: Integrates hot stamping process, allowing direct hot stamping of logos, production dates, etc., onto the packaging film. Speed can reach 160 packs/min.

Point-to-Point Four-Edge Embossed Pop-Up Facial Tissue Production Line

High-Speed Soft Pack Tissue Packaging Machine

Liuzhou Zhuode Machinery Technology Co., Ltd.

Automatic 14-Lane Four-Edge Embossing and Folding Machine: Uses airbag constant pressure technology for precise pressure application while extending the service life of the embossing rolls. Clear, delamination-free patterns. Capable of directly processing 2,800 mm wide parent rolls for higher production efficiency with speeds of up to 100 m/min.

Liuzhou Zoxin Automation Equipment Co., Ltd.

Multi-Function Pop-Up Facial Tissue Dual-Purpose Production Line: Uses a dual-channel design, allowing one-button switching between regular pop-up and bottom-up production modes. The first sheet uses an inward half-fold technology, improving the ease of pulling the first sheet after opening and preventing tearing. High operational efficiency with production speeds around 130 m/min.

Foshan Yanhe Intelligent Machinery Co., Ltd.

Automatic Paper Napkin Pouch Packing Machine: Uses paper pouch packaging. The pouches use coated water-based adhesive technology to ensure strength. Operating speed: 40 packs/min.

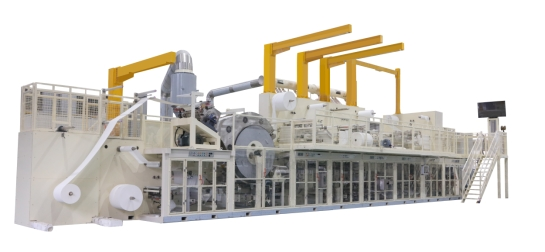

V. Machinery for Disposable Hygiene Products / Packaging Equipment Pavilion

1. Machinery for Disposable Hygiene Products. Ultrasonic and AI technologies find more applications; increased automation and speeds; more sophisticated equipment functions.

Anqing Heng Chang Machinery Co., Ltd.

High-Speed Online Core Commercial Application: Online composite core technology enables products with lower basis weight and thinner profiles, enhancing performance like water absorbency, breathability, and comfort. Can adapt to high-speed production exceeding 800 pieces/min.

Multi-Scenario Ultrasonic Technology Application: Hengchang continues to advance in ultrasonic technology application, with wider material adaptability, softer product feel, and stronger bonding capability.

Jinjiang Haina Machinery Co., Ltd.

Fully Servo Multi-Head Ultrasonic Baby Pant-Type Diaper Production Line: The product top sheet uses a composite process of through-air bonded nonwovens and spunbond nonwovens. Ultrasonic bonding technology enhances product softness. Equipment operating speed reaches 900 pieces/min.

Quanzhou Hanwei Machinery Manufacturing Co., Ltd.

Multi-Function High-End Adult Pant-Type Diaper Production Line: Uses ultrasonic welding technology for waist elastic joining. Stable production speed can reach 400 pieces/min.

Multi-Function Fully Servo Baby Pant-Type Diaper Production Line: Compatible with producing ultra-thin composite core and semi-composite core products. Stable production speed can reach 900 pieces/min.

Fully Servo Pet Diaper Production Line: Equipment operating speed can reach 600–800 pieces/min.

High-Speed, Intelligent Underpad Production Line: Equipment operating speed can reach 400 m/min, over 30% faster than traditional equipment, with a 20% reduction in power consumption.

2. Wet/Dry Wipes Machine. Wet toilet tissue packaging equipment and cotton soft towel equipment become industry favorites; interleaved pop-up folding technology emerges as a new highlight; packaging speed and appearance neatness remain key industry focuses; increased automation levels.

Rufong Machinery (Zhengzhou) Co., Ltd.

12-Lane Fully Servo Wet Toilet Tissue Production Line: Production speed can reach 640 cuts/min; improved equipment versatility and production efficiency. Added side compression exhaust function enhances product appearance quality. When using matte film packaging, packaging speed can reach 100 packs/min.

Zhengzhou ZLINK Machinery and Equipment Co., Ltd.

High-Speed Interleaved Pop-Up Wet Toilet Tissue Special Equipment: Solves the problem of discontinuous sheet dispensing for wet toilet tissue.

High-Speed Folded Wipes Production Line: Can be configured with different lane counts like 24, 40, 80, 100 lanes. The folder section of all production lines can operate half while the other half stands by for splicing, utilizing fully automatic online splicing technology. Production speed can reach 550–600 cuts/min.

Fully Automatic High-Speed Baby Wipes Packing Machine and Super Mini Wipes Production Line: Enables online replacement of wipes, packaging film, labels, closure tapes, etc., without stopping, improving production efficiency. Due to different packaging requirements, the average stable production speed can reach 100–130 packs/min, with the mini packer reaching 160 packs/min.

Quanzhou Quanchuang Intelligent Equipment Co., Ltd.

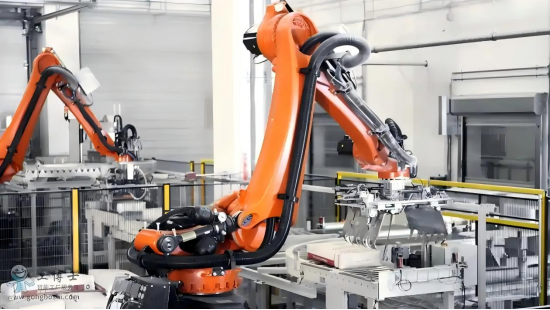

Intelligent Palletizing Workstation: Integrates Siemens control systems and KUKA industrial robots, featuring high load capacity and high-speed gripping capability. Capable of handling entire pallet loads at once, significantly improving palletizing efficiency.

Fully Automatic High-Speed Lid Applicator: Lid application speed can reach 120 units/min, greatly improving efficiency.

Zhengzhou Luchuang Machinery Co., Ltd.

Wipes Production Lines for Baby Wipes, Mini Wipes, etc.: Can adapt to different materials, including spunlaced nonwovens, wet-strength paper, biodegradable, flushable composite materials, etc. Suitable for basis weights of 35–80 gsm.

VIPPAI Machinery Co., Ltd.

Fully Automatic Four-Side Seal Wipes Packing Machine: Uses a multi-row, multi-point motion structure to improve product flatness. Packaging speed reaches 800–1,200 packs/min.

Horizontal Multi-Lane Intelligent Wipes Packing Machine: Supports free adjustment of the number of lanes. A new servo liquid pumping system allows precise adjustment of liquid addition volume, effectively improving stability and adaptability. Uses reciprocating edge sealing technology for more secure seal on wipes packaging.

Guangzhou Surprise Technologies Co., Ltd.

Fully Intelligent Interleaved Wet Toilet Tissue/Wipes Production Line: Features precise quantitative liquid addition, high automation, and is equipped with a fault early warning system, effectively improving production efficiency.

Fully Intelligent High-Speed Bottom-Up Cotton Soft Towel Production Line: Each functional unit uses independent full servo control and has self-diagnostic functions, ensuring stable and reliable equipment performance.

Guangzhou Explore Technology Co., Ltd.

Interleaved Wipes Intelligent Production Line: Uses vacuum constant pressure folding technology, increasing capacity and reducing energy consumption, while solving difficult dispensing and connected sheet issues. 3D spray technologies like pre-moistening, post-moistening, and combined pre/post moistening solve uneven product spray distribution.

N-Fold Cotton Soft Towel Bottom-Up Intelligent Production Line: Features easy-dispensing three-fold design, space-saving, and cost-effectiveness.

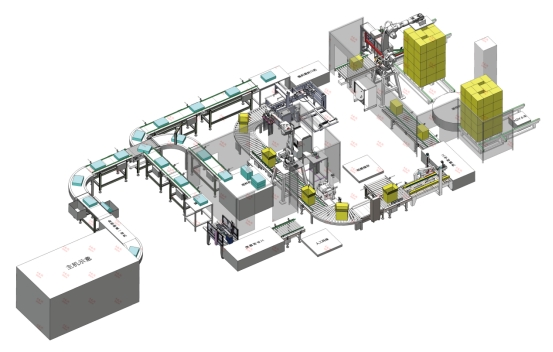

3. Packaging and Wrapping Equipment & Suppliers for Hygiene Products. Packaging production processes are increasingly automated, with rising operational speeds. Companies are able to offer a broader range of equipment, making end-to-end solutions the industry standard. At the same time, diversification and the adoption of new packaging materials are creating fresh opportunities in the hygiene products packaging sector.

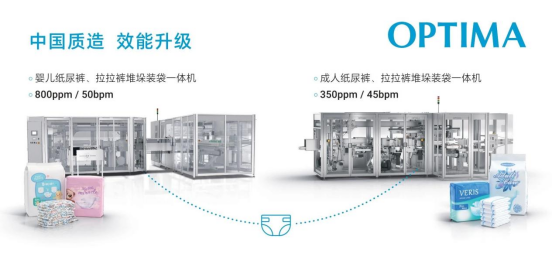

OPTIMA Packaging Machines (Shanghai) Co., Ltd.

Baby Diaper/Pant-Type Diaper, Adult Diaper/Pant-Type Diaper Bagging Machine: The equipment can match and run stably with upstream high-speed production lines. Stacking speed can reach 800 pieces/min, packaging speed 50 packs/min. Size change parts can be switched quickly within 15 minutes, delivering stable and efficient output. The equipment is suitable for green emerging packaging materials like paper packaging.

Xiamen Broad Mechanical & Electrical Engineering Co., Ltd.

Fully Automatic High-Speed Baby Diaper Stacker and High-Speed Packing Machine: Stable stacking speed reaches 1,000 pieces/min, stable packing speed reaches 50 packs/min. Allows quick switching of bag specifications and models. A unique sealing structure can reduce misalignment error to nearly zero, ensuring stable and efficient packaging speed.

Diaper Horizontal Small Pack High-Speed Packing Machine: Compatible with 4–12 piece packaging; speed can reach 60 packs/min.

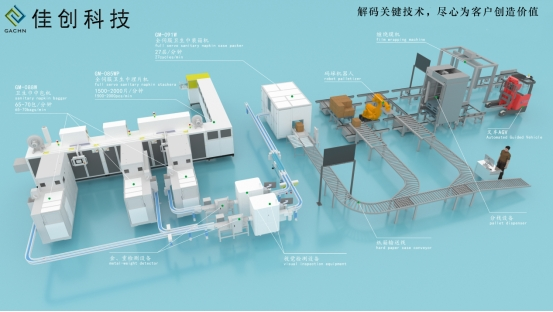

Xiamen Gachn Technology Co., Ltd.

Complete End-of-Line Intelligent Packaging Overall Solution for All Categories: Includes stacking, packaging, coding, inspection, automatic cartoning, automatic palletizing, automatic stretch wrapping, AGV inbound/outbound, and automatic truck loading. The product line can seamlessly connect with the user's MES/ERP systems, enabling visual management of production equipment status.

Shanghai Tominaga Packing Machinery Co., Ltd.

Fully Automatic Servo Sanitary Napkin/Pantiliner/Period Pant Packing Machine: Enables free switching between multiple products and multiple packaging formats. Packing speed for Sanitary Napkins/Pantiliners can reach 50–70 packs/min, for Period Pants 40–55 packs/min.

Fully Automatic Servo Sanitary Napkin/Pantiliner/Period Pant Vibratory Stacker: Stacking speed for Sanitary Napkins/Period Pants can reach 1,200 pieces/min, for Pantiliners 2,200 pieces/min. One unit can be configured with one or multiple stackers.

Fully Automatic Underpad/Pet Pad High-Speed Packaging Production Line: An intelligent complete line packaging system integrating stacking, packing, and cartoning machines, achieving fully automated operation throughout the process. Stacking speed can reach 1,000 pieces/min. Compatible with both insert-style and lay-flat bag loading methods.

Guangzhou Beixiaode Intelligent Technology Co., Ltd.

Online Multi-Level Four-Mode Coding and Traceability System: Dynamically adds attribute data to multi-level traceability codes at different process stages, solving multi-process traceability management challenges and improving data processing speed.

电话:010-64778188

电话:010-64778188  Email:cidpex@cnppri.com

Email:cidpex@cnppri.com