REVIEW

CIDPEX Review

Raw and Auxiliary Materials Pavilion

By Han Ying, Yu Miaoxuan, Li Yuchen, Ge Jiming, Zhang Shengyou, Wang Juan

Ⅰ. Nonwovens Pavilion: Diversified Technologies Drive Material Innovation

At the 32nd China International Disposable Paper Expo (CIDPEX), companies in the Nonwovens Pavilion showcased continuous innovation in material R&D, process optimization, equipment upgrades, and post-processing, with numerous highlights.

1. Spunlaced Nonwovens: Process Innovation, Multi-Functional Performance

Magnera

Sontara® branded spunlaced nonwovens use pulp fiber not treated with bleaching agents, delivering natural color and offering an eco-friendly solution. The Sontara® EcoRE eco-friendly bag, made from 100% cellulose fiber, has passed OK compost HOME home compostable certification.

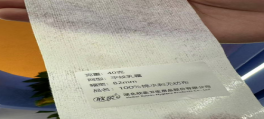

Xinjiang Zhongtai Henghui Medical Materials Co., Ltd.

Minsale® spunlaced nonwovens are produced using Minsale® fiber, which is prepared by dissolving and spinning cotton linter pulp from Xinjiang cotton. The product features high skin-friendliness, high softness, high water absorption, and low odor.

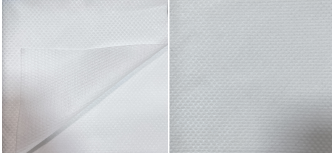

Hebei Hongrun New Material Co., Ltd.

Introduced German Trützschler high-blend three-card spunlace line capable of producing spunlaced nonwovens with basis weights from 35 gsm to 130 gsm. The products feature a low MD/CD strength ratio and more uniform cloth surface. They can provide differentiated nonwovens with an AB-sided "sandwich" structure.

Hubei Siling New Silk Medical Technology Co., Ltd.

Hydrophilic silk nonwovens made from new silkworm varieties offer 4x higher water absorption than degreased cotton. The product retains the natural antibacterial activity of silk cocoons and exhibits certain antibacterial effects against Staphylococcus aureus, Pseudomonas aeruginosa, and Candida albicans.

Eastex Industrial Science and Technology Co., Ltd.

l Spunlaced Nonwovens for Soft Towels: Utilizing a new CAC direct-laying process, it effectively solves the problem of transverse basis weight peaks and valleys distribution caused by the web-forming process, delivering a more uniform distribution and significantly improving product yield. Simultaneously, the cloth surface is 10% thicker compared to spunlaced nonwovens of the same basis weight, and the MD/CD strength ratio is optimized to 2.6:1, ensuring resistance to stretching and deformation.

l Spunlaced Nonwovens for Wet Wipes: Using a new CA direct-laying process, the material achieves a thickness 10%–15% greater than spunlace nonwovens of the same basis weight. When stretched transversely, its stress performance is 10%–40% higher, delivering strong tensile resistance with no deformation or clumping. The longitudinal-to-transverse strength ratio is boosted by 40%–50% and optimized to 2.2:1 comparable to semi-cross-lay technology, delivering outstanding tear resistance and durability.

Hubei Xinrou Hygiene Products Co., Ltd.

l Its all-cotton spunlaced nonwovens production line incorporates AI cloth inspection machines for online defect detection, delivering more stable product quality.

l Its plain, lotion-type all-cotton spunlaced nonwovens are added with lotion, making the product softer and more skin-friendly.

Zhejiang Dekang Environmental Protection Co., Ltd.

l Wood Pulp Wet-laid Spunlaced Nonwovens for Surface Wiping: With a wood pulp addition ratio exceeding 80%, it addresses the pain points of wood pulp nonwovens such as easy linting, thinness, black spots, and low breaking strength. It fully utilizes the adsorption performance of the porous structure of wood pulp fibers to meet multi-scenario wiping needs.

Unbleached Bamboo Pulp Flushable Nonwovens: Using unbleached bamboo pulp instead of wood pulp solves the problems of severe fine fiber loss during production and linting during application, achieving a balance between breaking strength and flushability to meet product application requirements.

2. Hot Air-through Nonwovens: Optimized Process, Enhanced Performance

Xiamen Yanjan New Material Co., Ltd.

Its hot air-through nonwovens adopt 3D Plus perforated embossing technology, achieving different embossing combinations between the center and edges of the nonwoven through post-processing, forming a "leak-proof barrier" on the nonwoven surface to prevent side leakage.

Anqing Fengge Nonwoven Co., Ltd.

Its new "Coarse Denier, Fine Touch" hot air-through nonwovens utilize special melt spinning and through-air bonding processes, giving coarse denier fibers the feel of "fine denier" fibers, along with high elasticity, high loftiness, and a three-dimensional sense. They feature fast liquid penetration, no residue, and certain anti-reverse seepage capability. The top sheet nonwoven uses a post-process 3D embossing technique to maintain a three-dimensional appearance and a dry, breathable user experience.

Wisdom-Greentech Company Limited

Its perforated, embossed, double-layer composite, punched nonwovens enhance product breathability, softness, and three-dimensional feel through two post-processing techniques: perforation and embossing.

3. Spunbond and Elastic Nonwovens: Breakthroughs in 3D Structure and Elastic Function

Shandong Dawn SWT Technology Co., Ltd.

l Side-by-Side Bicomponent "3D Liquid Cotton" Spunbond Nonwovens: Use small spiral crimped fibers, delivering a soft texture and enhanced skin-friendliness. Compared to Hot air-through Nonwovens, they feature continuous filaments and disordered uniform web formation that reduces friction.

l Spunbond Side-by-Side Bicomponent "Jin Rou Bico-L1/L2/L3 Series" Nonwovens: Based on fiber crimping, use finer fibers (fiber fineness 1–1.5D), making them softer, more skin-friendly and stable for high-speed processing.

Magnera

Its new product, Elastipro® elastic nonwovens, boasts high extensibility of up to 700% in all directions. It features high extension recovery, soft hand feel, gentle skin fit, along with good breathability and moisture permeability. The special fiber structure effectively prevents the penetration of fine dust particles. The product is available in various basis weights from 20 gsm to 300 gsm.

4. Fiber Materials: Focus on Environmental Protection, Functional Segmentation

Sateri

l New Generation Lyocell Fiber: 100% biodegradable, soft and tough, does not shed.

l EcoCosy Fiber: Features excellent skin-friendliness, water absorption, and moisture diffusion. Applicable in various segments such as wipes, beauty, and flushable products.

Fujian MR Fiber Joint Co., Ltd.

l 0.6D Ultra-Fine Denier Cloud-Soft Fiber: Softer and silkier, with high loftiness and high breathability. Uses bicomponent composite PE/PET material technology to enhance various physical indicators of the fiber.

l Eccentric 3D Spiral Fiber: Uses a unique processing technology to form a three-dimensional crimp form, featuring natural loftiness and high resilience after compression.

Shandong Hongtaiding New Material Technology Co., Ltd.

l Its "Jin Xian" Lyocell fiber is produced using a dry crushing-direct dissolution-dry-jet wet spinning process. The product uses pulp made from natural plant fibers as raw material and is biodegradable.

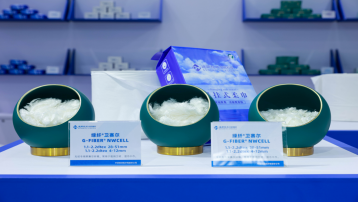

China Textile Academy Green Fibre Co., Ltd.

Its G-FIBER NWCELL® Lyocell fiber offers advantages of "Green, Pure, Soft" compared to traditional fibers. "Green" is reflected in the closed-loop process, recyclable solvent, raw materials sourced from sustainable forests, energy-saving production, and natural degradability. "Pure" refers to a cellulose content as high as 99.9%, removal of metal ions during production, no chemical residues, and no odor. "Soft" means the product has a smooth surface and a delicate hand feel. It also possesses the three key characteristics: "flushable, biodegradable, strong water absorption".

5. Cores and Airlaid Pulp: High Efficiency, Environmental Protection, Technological Upgrades

Wuhan Gerowa Technology Co., Ltd.

Its ultra-cool core for sanitary napkins provides ultra-cool sustained release for over 3 hours during use. The company's product also solves the problem of cooling agent loss during transportation and storage, making it an ideal choice for long-distance transport.

Guangdong Meiden Paper Products Co., Ltd.

l The thermal fusion integrated molding composite core (abbreviated as "one-piece core") is launched, with enhanced absorption performance.

l Developed airlaid pulp containing Super Absorbent Polymer (SAP).

https://media/image25.jpeg{width="2.5270833333333334in"

Unicorn Nonwovens Co., Ltd.

Its Muroufang® airlaid nonwovens are produced on a self-developed fully automatic high-speed multi-row hole, multi-fiber blended airlaid nonwoven material production line. Using fluff pulp as raw material and combined with degradable modified polypropylene, the product is environmentally friendly and applied in dry/wet wipes products.

II. Packaging and Printing Pavilion: Environmentally-friendly, Efficient, Reduced Cost

Fujian Minghe New Materials Technology Co., Ltd.

l Uses flexographic printing equipment, characterized by low residue, high precision, high speed, and low waste.

l Its PE composite embossed bags use composite technology, preventing color fading and offering a good hand feel.

l Its environmental European-style bag is more convenient for consumers to carry compared to ordinary European-style bags. Simultaneously, the handle part is more upright, making it easier to display on shelves.

Lanxi Jiahua Plastic Co., Ltd.

Uses In-Mold Labeling technology, where the label is directly embedded into the wipes lid during the injection molding stage, reducing 2–3 steps required for traditional labeling, improving yield rate while lowering overall costs.

Jinwanzheng (Guangdong) New Materials Co., Ltd.

Its hard lid labels for wipes packaging can directly work as a wipes lid, saving packaging costs.

Hebei Tanke Plastic Industry Co., Ltd.

Uses In-Mold Labeling technology for wipes lids, where a pre-printed label is placed into the mold cavity by a robotic arm, fusing with the lid instantly during injection molding. Its price is only half that of labels with adhesive, significantly reducing production costs for wipes manufacturers. Simultaneously, IML allows direct labeling on recessed lid areas, offering greater precision compared to ordinary labeling methods. The wipes production process eliminates the labeling step, simplifying the workflow.

III. Super Absorbent Polymer (SAP) Pavilion: Enhanced Performance in Antibacterial/Odor Control, Absorption Speed, Absorption Capacity, and Retention

Satellite Science & Technology Co., Ltd.

Its new fragrance sustained-release SAP uses technologies for antibacterial/urease inhibition, physical adsorption, and fragrance sustained-release for odor control, effectively improving the odor control effect in absorbent hygiene products.

Wanhua Chemical (Yantai) Trading Co., Ltd.

Its WANICE® WHS1200 SAP features fast absorption, high permeability, and low extractable content. The minimum free absorption capacity is 55 g/g. It is highly suitable for ultra-thin cores that have extremely high requirements for absorption speed and liquid strike-through speed.

Taisu Industries (Ningbo) Co., Ltd.

Its NB703 SAP has passed FDA safety certification (FCN 2396) and offers higher retention capacity and better absorption speed.

Shandong Haoyue New Materials Co., Ltd.

Its deodorizing SAP has significant advantages in absorbency, odor absorption capability, lock-liquid capability, and fragrance capability. It exhibits excellent deodorizing effect on ammonia.

IV. Hot Melt Adhesive Pavilion: Excellent Bonding Performance, Wide Applicability, Green and Environmentally-friendly

Dongguan CO-MO Adhesives Co., Ltd.

Its UV acrylate hot melt pressure sensitive adhesive offers good weather and aging resistance. It exhibits excellent bonding performance to various nonwoven materials, PE, PP, etc. When used for sanitary napkin back adhesive, the long-term peel strength retention rate can reach over 95%, ensuring stable quality. The product features low odor and low VOC.

Bostik (Shanghai) Management Co., Ltd.

Kizen™ PAD is a back adhesive specifically designed for sanitary napkins. It features high adhesive performance, suitable for different types of underwear fabrics such as cotton, nylon, modal, silk, lyocell, polyester, etc., and also suitable for highly breathable backsheets, offering excellent bonding performance. While maintaining identical performance, the adhesive usage can be reduced, and the backing adhesive will not move or transfer.

V. Other Raw and Auxiliary Materials Pavilion

1. Balm, Surfactant, Additive: Application of Probiotics and Natural Ingredients

Fujian Luodong Biotechnology Co., Ltd.

Its new probiotic antibacterial solution involves customizing the precise ratio of various probiotics and fixing the beneficial bacteria on the surface of wipes or organic cotton substrates. Substances like bacteriocins and organic acids produced by the metabolism of these bacteria can efficiently destroy the cell membranes of E. coli and Staphylococcus aureus, achieving an antibacterial rate exceeding 99.9%, while avoiding the sensitization risks associated with chemical antibacterial agents.

Beijing Sunpu Biochem. Tech. Co., Ltd.

l

Its preservative uses cyclodextrin encapsulation technology, significantly improving the solubility and stability of active ingredients, while reducing discoloration issues in wipes products caused by high temperature or light exposure.

l

Its antibacterial agent uses a natural synergistic system, specifically a compound formulation of p-hydroxyacetophenone and clove flower extract. The synergistic effect not only significantly enhances antibacterial efficacy, but also effectively reduces the probability of product yellowing.

2. PE Film, Plastic Masterbatch: Breakthroughs in Biodegradable and High-Filling Technologies

Innova Packaging Group

l

Its biodegradable small packaging film, breathable backsheet, and packaging bags for hygiene products use a blend of PLA (polylactic acid) and PBAT (biodegradable polyester) as raw materials. The safety is superior to traditional PE film, and they can completely degrade within 6–12 months under composting conditions.

l

Its Bio-PE film uses renewable resources as raw materials, with performance similar to traditional PE materials, stable tensile strength, and is more environmentally friendly.

Guangdong Tenghua Yuehang Hygiene Materials Technology Co., Ltd.

Its one-step breathable film production line, equipped with automatic thickness control and automatic winding systems, addresses the challenges of large equipment footprint and high operator skill requirements that typically accompany breathable film production. Using a single production line, it can complete the process from raw material processing to finished product output, saving space, reducing labor costs, and improving production efficiency.

|

|

Shuangcheng Plastic Master Batch Co., Ltd.

Through process optimization of the masterbatch coating layer, it has increased the talc content in the masterbatch to 80%, breaking through the traditional 60% filling limit. Simultaneously, the Melt Flow Rate (230°C/2.16 kg) is maintained at 2–8 g/10min, moisture content is controlled at ≤0.3%, and ash content is controlled within the standard value ±1.5%, avoiding the risk of thermal degradation due to moisture.

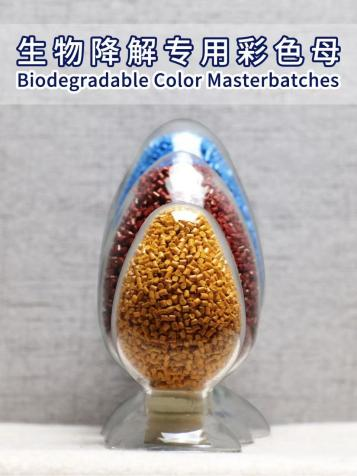

Zhejiang Hongye New Materials Co., Ltd.

Its biodegradable color masterbatch is formulated using fully biodegradable base materials, specialized dispersants, and eco-friendly pigments. It is made into specialized biodegradable material through modification technology and special processes. The content of non-biodegradable components is less than 1%. It can be applied in fields such as films, injection molding, and thermoforming.

3. Elastic Materials: Lightweight, Sustainable

The LYCRA Company

l Its newly launched T937 LYCRA HyFit® fiber uses special polymer materials originating from the apparel field. Its high elasticity and soft stretching characteristics bring dynamic comfort to disposable hygiene products like diapers and adult incontinent pants, enhancing fit and achieving stability without shifting.

l

|

Its bio-based spandex fiber has 70% of its raw materials derived from corn, making it more environmentally friendly.

Huafon Chemical Co., Ltd.

l The newly launched Qianxi® spandex for hygiene materials comes in various specifications, supporting stable bidirectional unwinding (both forward and side directions). It meets the requirements of reducing tension fluctuation and basis weight, while featuring high temperature resistance and aging resistance, making it suitable for the thinning design of diapers, sanitary napkins and other hygiene products. The product boasts outstanding high elasticity and other characteristics, as well as a distinct cost advantage.

Its multi-color spandex fiber and its preparation method have obtained a national invention patent. This technology enhances the product's aesthetics while maintaining the original spandex performance, meeting personalized design needs.

4. Pulp, Fluff Pulp: Technological Innovation, Application Expansion

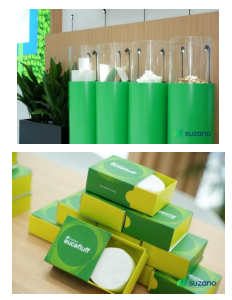

Suzano

l Suzano Biopulp Eucalyptus Pulp: Features good fiber uniformity, achieving a balance between product strength and softness. Through professional pulp blending technology, this pulp can effectively replace softwood pulp. It has achieved pilot and large-scale production of tissue products using 100% Suzano Biopulp eucalyptus pulp in a domestic company, with product performance indicators meeting national standard requirements.

l Eucafluff® Eucalyptus Fluff Pulp: Offers good anti-reverse seepage performance and comfortable experience, realizing the large-scale application of hardwood (eucalyptus) fluff pulp in the hygiene products field.

电话:010-64778188

电话:010-64778188  Email:cidpex@cnppri.com

Email:cidpex@cnppri.com