REVIEW

CIDPEX ReviewEquipment Pavilion: Energy Savings and Smart Upgrades Drive Efficient Production

By Guo Kaiyuan, Xing Wanna

At this year’s CIDPEX Exhibition in Nanjing, the tissue paper machinery and related apparatus pavilion featured nearly 100 equipment manufacturers, showcasing energy-saving, digitalized, and intelligent machinery and components, helping enterprises enhance quality and efficiency.

Scan the QR code to view highlights in the tissue paper machinery and related apparatus pavilion.

Tissue Paper Machinery and Related Apparatus Pavilion: Energy Saving and Consumption Reduction Remain the Development Trend for New Technologies

Andritz (China) Co., Ltd. brought multiple energy-saving and consumption-reduction related technologies. Their high-consistency refining stock preparation technology reduces long-fiber pulp usage by 15%, allowing the paper sheets to achieve higher strength and bulk while significantly cutting production costs. The PrimePress XT Evo shoe press technology achieves a post-press dryness of up to 47.6%, significantly reducing subsequent drying energy consumption and enabling higher sheet bulkiness. The Yankee cylinder hybrid gas-electric heating system aims to substantially reduce paper mill carbon emissions and optimize energy costs. Andritz's Fiber Quality Navigator: Fiber GPS™ stock preparation system (especially pulp mixing and refining) helps reduce the Total Cost of Ownership (TCO) for paper enterprises through automation and digital means.

Toscotec S.p.A. focused on exhibiting their upgraded next-generation shoe press, third-generation Toscotec steel Yankee cylinder, TT bulkyReel for maintaining optimal bulkiness and softness, automatic drying balance system TT drying equilibrium, and efficient hoods, representing the latest technologies in energy saving and consumption reduction for tissue machines.

Tissue Converting Machinery and Packing Machinery: Balancing High Efficiency and Flexibility

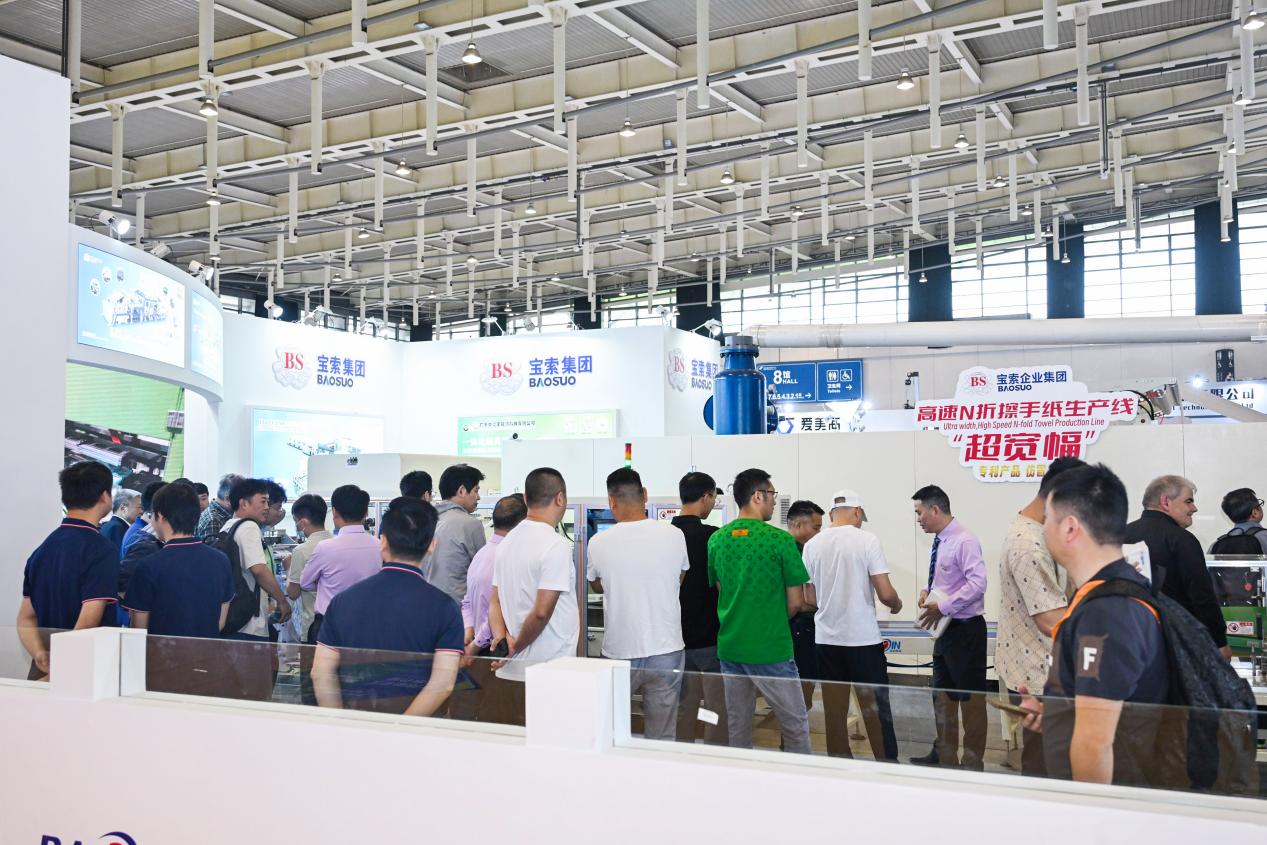

At this CIDPEX exhibition in Nanjing, over 50 equipment manufacturers participated in. With rapid market changes, exhibitors placed greater emphasis on the efficiency and flexibility of their equipment to meet customer demands for highly efficient production.

Foshan Baosuo Paper Machinery Manufacture Co., Ltd. displayed their newly developed "super-wide" high-speed N-fold Hand Towel production line. The folding roller utilizes a hollow constant-pressure adsorption principle, reducing fan suction loss, making the paper more uniform, ensuring flat and stable paper surface during high-speed operation, and resulting in neat and aesthetically pleasing folds.

OK Science and Technology Co., Ltd. exhibited soft pack facial tissue production lines, handkerchief tissue production lines, moisturizing toilet tissue production lines, and various packaging films for tissue paper and hygiene products. They provide comprehensive integrated turnkey solutions for customers, from tissue parent rolls to finished products, including intelligent production and processing equipment, as well as printing films for soft tissue packaging.

Dechangyu Paper Machinery showcased high-speed printing solutions supporting two-color or four-color printing, compatible with toilet tissue slitting and rewinding, with a production speed of up to 400 m/min. It features quick plate change functionality for rapid product transition. Dechangyu's patented one-touch cleaning function allows automatic cleaning without web break, greatly reducing cleaning downtime and parent roll loss. Rewinding production lines operate at speeds and capacities 10%–25% higher than the previous generation. Folding production lines can produce conventional facial tissue and multi-pack bottom-draw products, meeting diverse production needs.

Guangdong Zhidesheng Technology Co., Ltd. exhibited a new high-speed rewinding machine with a stable operating speed of 500 m/min, offering higher precision, quieter operation, lower energy consumption, and a longer service life.

Zhejiang Onepaper Smart Equipment Co., Ltd. showcased a new generation of fully automated facial tissue production lines, characterized by intelligence, system integration, high aesthetic appeal, and exceptional efficiency. It allows one-touch switching from 30 to 200 sheets, compatibility from 11.5 g/m² 2-ply to 5-ply paper, and one-touch switching for four-sided registered embossing specifications. Additionally, it is equipped with a remote IoT system, enabling real-time production monitoring via a mobile app.

Shanghai Songchuan Fengguan Packaging Automation Co., Ltd. launched fully automatic soft pack facial tissue production lines, cotton soft towel production lines, 4D embossing tissue production lines, intelligent hygiene products packaging lines, and back-end boxing and palletizing products. They also offer production lines for the currently popular bottom-draw products, providing complete line layout solutions to achieve win-win cooperation with customers and standardized, efficient production.

At this CIDPEX exhibition in Nanjing, the disposable hygiene products machinery and packaging equipment machinery pavilion featured over 160 equipment manufacturers, including machinery for producing sanitary napkins, baby diapers/pants, adult incontinent products, wet wipes, detecting instruments, and various packaging equipment. Disposable hygiene products machinery manufacturers have upgraded their equipment, maximizing intelligent applications while optimizing automation levels and compatibility, facilitating production enterprises in achieving higher efficiency. Hygiene products packaging equipment manufacturing focuses on greater stability, efficiency, flexible changeover, and human-centric design to support producers' diverse back-end packaging needs.

Scan the QR code to view highlights in the disposable hygiene products machinery and packing machinery pavilion.

Ø Disposable Hygiene Products Machinery Pavilion: Intelligent Upgrades, Enhancing Both Automation and Compatibility

China National Pulp and Paper Research Institute Co., Ltd. launched a diaper absorption performance tester. It can automatically complete functions like liquid addition, constant pressure application, and timing during the test process, and measure absorption performance indicators such as absorption rate under pressure, rewet, and leakage. It utilizes a servo motor and high-precision ball screw transmission for accurate stroke control and a high level of intelligence.

Haina Intelligent Equipment International Holdings Ltd. promoted the HNJX-CLK500 pant-type adult incontinent products/menstrual pants production line. This equipment can accommodate the production of different specifications of pant-type adult incontinent products and is compatible with producing pants for women's menstrual period. It offers superior performance, achieving zero speed differential bonding without the need to change the cross-direction variable speed mechanism. It employs an advanced human-machine system and ultrasonic waistband welding technology, enhancing welding torque, improving product softness, and resolving material stretching issues caused by tension during material changeovers.

HNJX-CLK500 Pant-type Adult Incontinence Products/Menstrual Pants Production Line

Anqing Heng Chang Machinery Co., Ltd. launched its 500 PPM Adult Incontinent pants production equipment. This equipment operates stably, accelerates quickly, and maintains stable product quality. It enables efficient production with high modularity and intelligence, and can be paired with different packaging machines to meet various packaging needs like single or double row packaging. The equipment is independently designed and manufactured, possessing complete independent intellectual property rights and offering higher cost-effectiveness.

500 PPM Adult Incontinent Pants Production Equipment

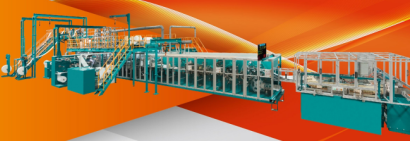

Jiangsu JWC Machinery Co., Ltd. showcased its ultra-high-speed under pad production equipment. Utilizing the latest high-speed forming system, it offers a maximum pulp supply capacity of 1,500 kg/h, an operating speed of up to 400 m/min, and simultaneously reduces energy consumption by 20%, helping enterprises reduce cost and enhance efficiency.

Ultra-High-Speed Under Pad Production Equipment

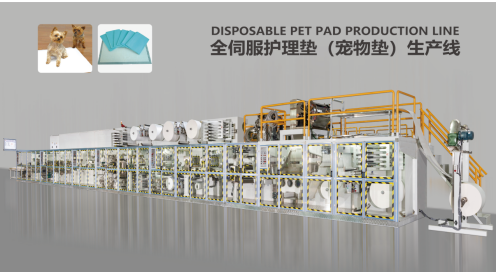

Quanzhou Zhigao Machine Co., Ltd. displayed its all-servo under pad (pet pad) production line. The equipment adopts a modular compact design, is easy to operate and maintain, has low energy consumption, and high production efficiency. It features automatic detection of missing raw materials and automatic waste rejection, and can automatically alarm when air pressure is insufficient.

All-Servo Under Pad (Pet Pad) Production Line

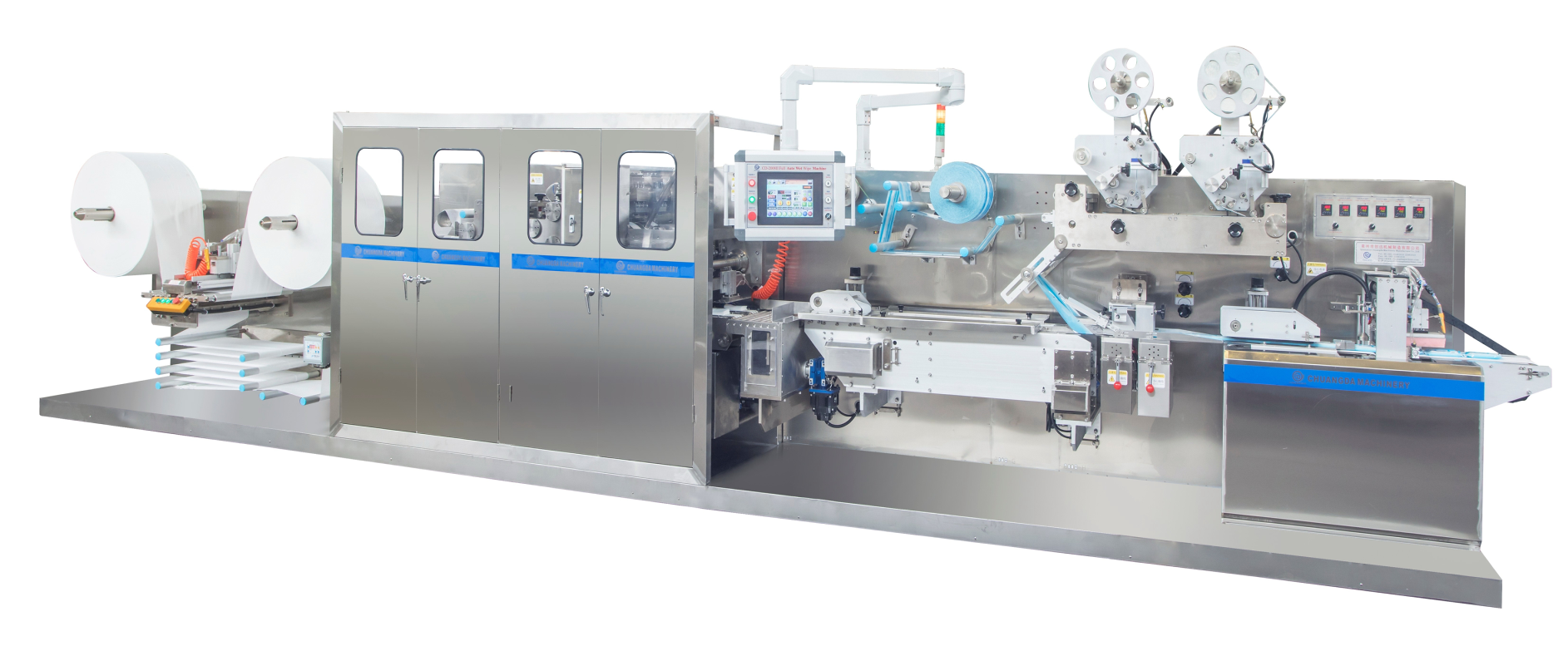

Zhengzhou ZLINK Machinery and Equipment Co., Ltd. showcased the WT-IF16 wet wipes production line at this exhibition. It employs an electrical safety loop design complying with CE safety standards, allowing non-stop changeover of nonwovens, roll film, and other materials. Automatic label splicing significantly reduces downtime and effectively improves work efficiency. Online detection of cloth splices and online rejection of splice joints ensure product quality. It is equipped with dual differential unwind stands, allowing large and small rolls to run synchronously.

WT-IF16 Wet Wipes Production Line

Zhejiang New Yuhong Intelligent Equipment Co., Ltd. showcased the CSG-AD350 all-servo adult incontinence products production line. It can produce both tape-style and pant-type adult incontinence products, with convenient and quick one-touch specification changeover, reducing waste generated during changeovers. It is configured with a modular high-density ultra-thin absorbent core forming system and automatic deviation correction device, enabling online production of ultra-thin cores.

CSG-AD350 All-Servo Adult Incontinence Products Production Line

Quanzhou Chuangda Machinery Manufacture Co., Ltd. showcased the CD-2008D 5-30 piece wet wipes machine. The folding machine can achieve automatic non-stop changeover of nonwovens raw material, reject nonwovens splices, and automatically alarm and stop when material breaks. The packaging machine uses a dual web stand for the wrapping film, reducing material changeover time.

CD-2008D 5-30 Piece Wet Wipes Machine

Nordson (China) Co., Ltd. showcased two major upgrades at this exhibition:

The first is "Application Upgrade." The Harmony integrated high-performance platform, originally supporting the full range of adhesive application (continuous/intermittent spraying, continuous/intermittent slot coating), has added "Breathable Coating" application. This helps enhance the softness, breathability of disposable hygiene products and saves costs.

The second is "Product Upgrade," focusing on the newly upgraded AltaCoat-i intermittent slot gun, AltaSpray-i intermittent spray gun, and the blue series hoses. The upgraded guns offer more stable performance. The upgrade of the blue series hoses improves thermal conductivity, provides stable temperature, saves energy, and reduces charring.

Harmony Integrated High-Performance Platform

AltaCoat-i Intermittent Slot Gun, AltaSpray-i Intermittent Spray Gun, and Blue Series Hoses

Ø Disposable Hygiene Packing Machinery Pavilion: Human-Centered Design: Flexible, Stable, and Precisely Aligned with Customer Needs

|

|

OPTIMA Packaging Machines (Shanghai) Co., Ltd. (OPTIMA) showcased the packaging machine specifically designed for tape-style and pant-type baby diapers the localized model BDS3. This model still uses core components such as the US AB system, German FESTO pneumatic components, and German Alpha Wittenstein planetary reducers to ensure stable, reliable, and durable operation. Feed speed is 800 pieces/min, and packaging speed is 50 packs/min.

Tape-style, Pant-type Baby Diapers BDS3 Packaging Machine

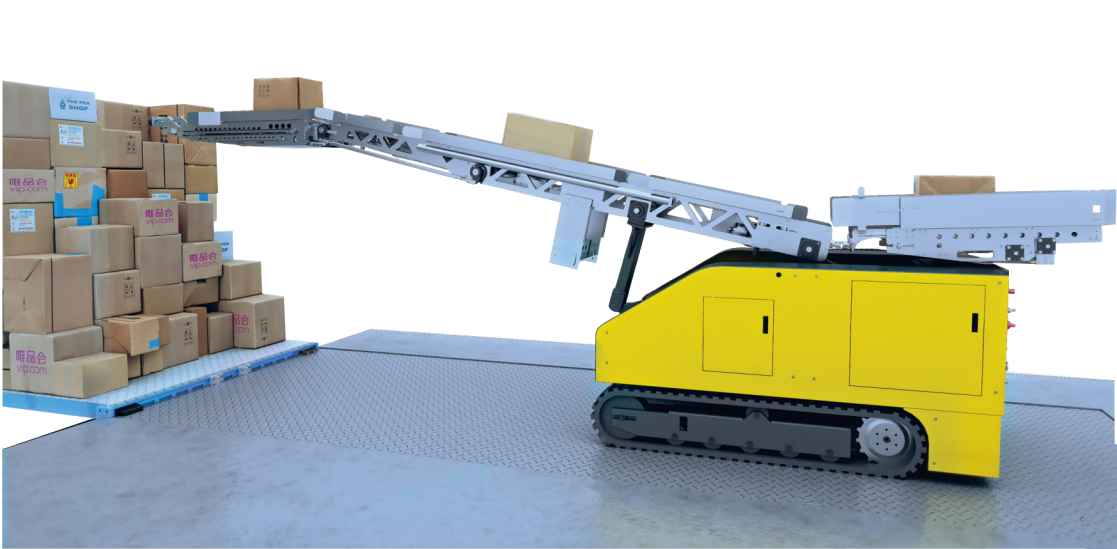

Xiamen Gachn Technology Co., Ltd. launched an intelligent unloading robot. It can interface with manual palletizing or flexible intelligent unloading systems and automated storage/retrieval systems (AS/RS) for automatic palletizing, widely suitable for unloading requirements in different scenarios like vans and container trucks. Using 3D visual recognition technology, it can accurately identify the position and posture of cartons, achieving flexible grasping of cartons with different stack patterns and sizes, meeting users' unloading needs for multiple cartons of varying sizes, thereby saving labor.

Intelligent Unloading Robot

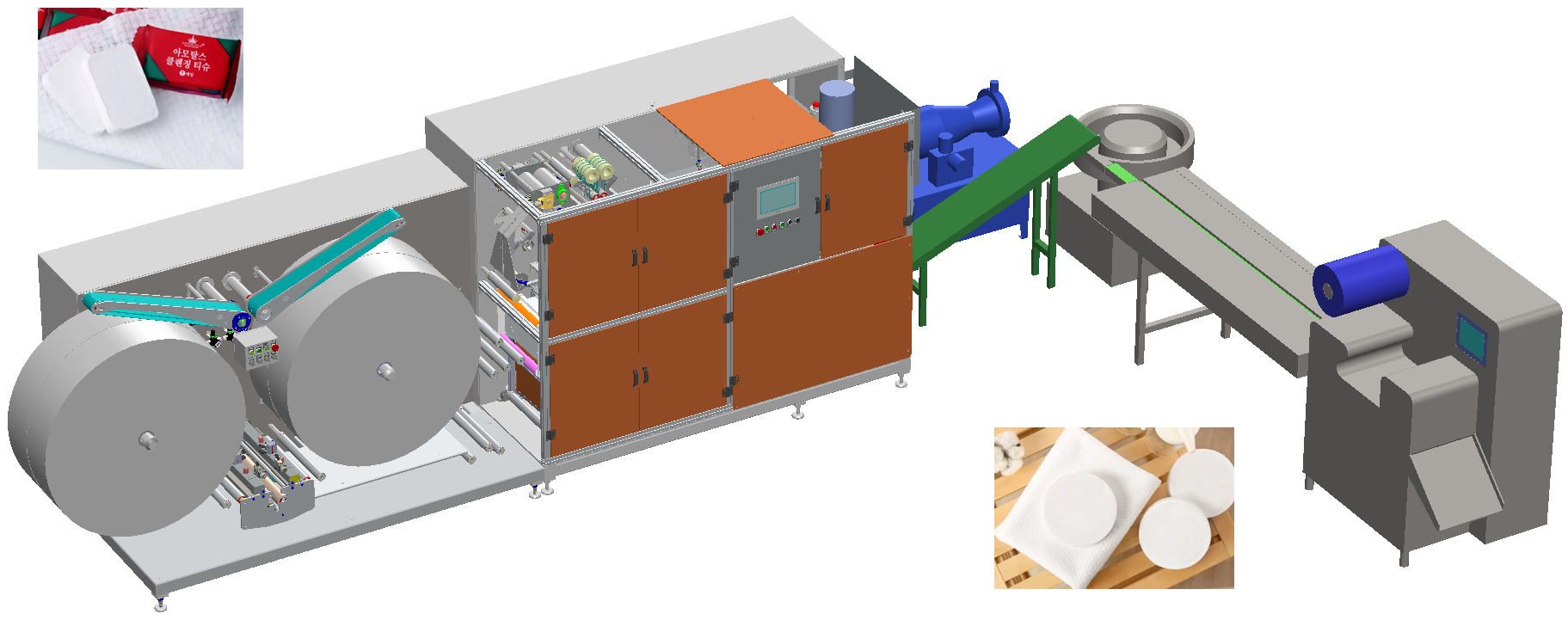

Xiamen ForePak Machinery Co., Ltd. showcased the FP8900 fully automatic high-speed compressed towel production line. It realizes the fully automatic, high-speed production process of compressed towels from cutting, folding, compressing to packaging, eliminating human contact with the product, ensuring safety and hygiene.

FP8900 Fully Automatic High-Speed Compressed Towel Production Line

Xiamen Broad Mechanical & Electrical Engineering Co., Ltd. showcased its all-servo high-speed packaging machine (automatic size change) with exclusive patented technology. It features a unique corner insertion forming process that can precisely control the corner insertion mechanism to adapt to different packaging sizes, ensuring stable and aesthetically pleasing corner insertion. The equipment integrates a one-touch size change system and adopts an all-servo design, offering high stability and wide applicability. The human-machine interaction is user-friendly, allowing different product parameters to be saved and read, making size changes convenient and fast.

All-Servo High-Speed Packaging Machine (Automatic Size Change)

电话:010-64778188

电话:010-64778188  Email:cidpex@cnppri.com

Email:cidpex@cnppri.com