REVIEW

CIDPEX ReviewTissue Paper Machinery and Related Apparatus—New Technologies Tailored for the Local Market

Scan the QR Code to View Highlights from Tissue Paper Machinery, Related Apparatus and Tissue Converting Machinery Pavilion

New technologies are a key driver of industry development. As new technologies like TAD and TAD-like tissue machines enter the domestic market, their transformative impact is becoming increasingly evident, driving high-quality development in the industry. Companies are also launching tissue machine equipment that is more suitable for the local market.

Andritz (China) Ltd. highlighted the Prime LineHyTAD textured tissue machine, which delivers TAD-comparable tissue quality at a lower production cost. Compared to conventional dry-crepe tissue machines, it can save up to 25% in fiber usage; compared to TAD machines, it can save up to 50% in energy consumption.

Andritz also introduced the PrimePress XT Evo shoe press, which reduces energy consumption and improves sheet bulk. Owing to an optimal nip pressure curve and minimal sheet re-wetting, operating the shoe press in Dryness Mode achieves higher dryness after pressing. When run in Bulk Mode, the shoe press can produce sheets with higher bulk.

Toscotec S.p.A. newly launched the Ingenia tissue machine. Utilizing Toscotec’s unique speed differential transfer wet-creping and structured wire dewatering technology, it produces paper with high bulk, high absorbency, and high softness. Its energy consumption falls between that of conventional crescent tissue machines and TAD machines.

Furthermore, Toscotec introduced the Induction SYD Yankee Dryer, which uses electric induction instead of steam energy to dry the paper, thereby reducing greenhouse gas emissions to zero.

Tissue Converting Machinery and Packing Machinery—Intelligence + Automation, Robots Emerge as New Highlight

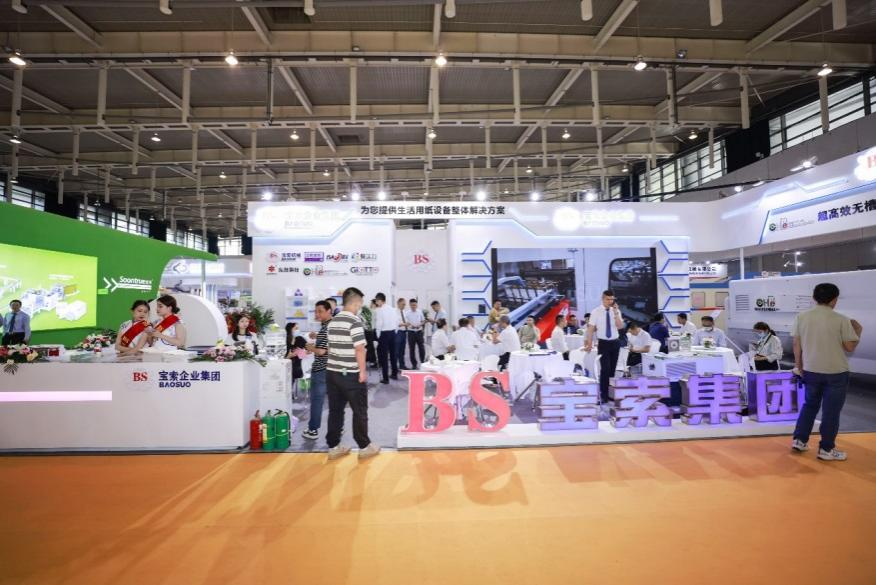

Baosuo Paper Machinery Manufacture Co., Ltd. exhibited the YH-FG Automatic Facial Tissue Production Line (including a supporting packaging machine). The equipment features position embossing with water lamination. Among its features, “3D internal weaving, glue-free lamination” is Baosuo’s innovative and environmentally friendly technology for tissue paper intelligent equipment, making products more eco-friendly, hygienic, and higher quality, while also being clean, aesthetically pleasing, soft, and skin-friendly.

Zhejiang Onepaper Smart Equipment Co., Ltd. exhibited a fully automatic facial tissue folding machine. It offers stable product quality, one-touch switching between different product specifications. It is compatible with 2- to 5-ply tissues, including those with a basis weight of 11 g/m². Options include steel-to-rubber/steel-to-steel embossing, adhesive lamination embossing, and four-edge registered embossing, meeting various customer needs.

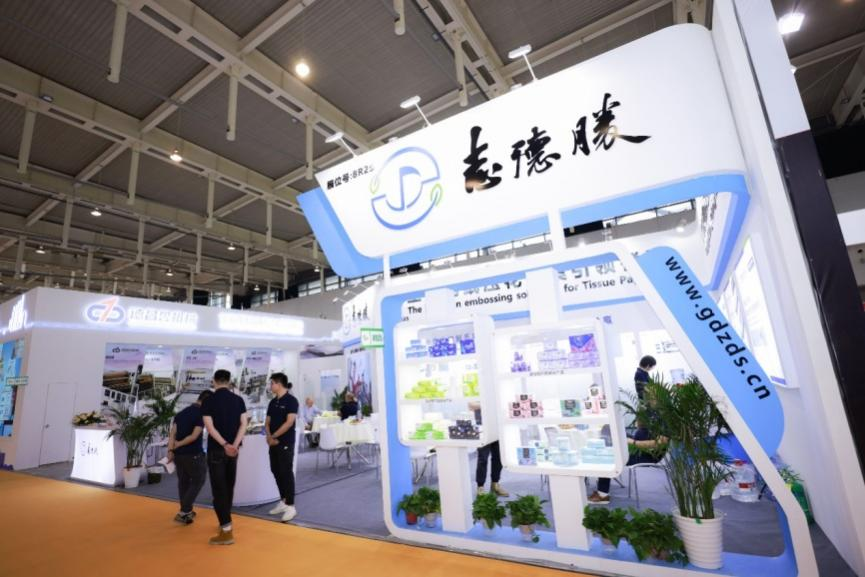

Guangdong Zhidesheng Technology Co., Ltd. offers more diversified embossing solutions through its variety of embossing units. These include: a multi-functional double-sided 3D embossing unit suitable for toilet tissue; a facial tissue glue-free 3D embossing unit with a wide applicable paper web width and broad production speed range, capable of automatically matching the production line speed, providing reliable bonding resistant to delamination; and a four-roller/double-roller point-to-flat embossing unit for facial tissue/toilet tissue production lines, featuring purely physical glue-free embossing/bonding and automatic synchronization with the production line speed.

Tech.Vantage International Ltd. highlighted the ASV Line from OMET, specifically developed for interfolded paper towels, kitchen towels, facial tissues, and toilet tissues. The automatic line for interfolded products operates at high speeds with full automation, is easy to operate, allows for quick master roll and knife changes, optimizes production time, and reduces waste. The patented vacuum constant pressure technology makes maintenance of the folding rolls extremely simple.

Körber showcased the Körber ecosystem, which connects all equipment across a production line–including machinery from companies outside the Körber Group–from parent-roll unwinding to finished-product palletizing. The system automatically optimizes key production parameters for higher efficiency and ensures the finished product meets desired specifications, thereby best fulfilling customer requirements.

Chaint Corporation focused on promoting technologies, such as automated warehousing. Its integrated solutions span the entire process: from front-end fully automated pulp preparation systems, automated paper roll conveying and packaging systems, to back-end finished product small-item conveying systems, full-layer small-item palletizing systems, fully automated circular shuttle cars, intelligent Automated Storage and Retrieval Systems (AS/RS), and fully automated intelligent truck loading systems. This achieves automation, intelligence, and digitalization from pulp preparation and paper roll conveying to packaging, conveying, palletizing, and warehousing.

At this CIDPEX in Nanjing, the Disposable Hygiene Products Machinery and Packing Machinery Pavilion featured over 150 equipment manufacturers, showcasing machinery for producing sanitary napkins, baby diapers/pads, adult incontinence products, wipes, as well as testing equipment, automation equipment, and various packaging machines. Hygiene products machinery manufacturers collectively exhibited digital, intelligent, and automated operational equipment and supporting components, contributing to improving product quality and production efficiency. Packaging equipment for hygiene products demonstrated more flexible and user-friendly operation, capable of meeting diverse packaging requirements.

Scan the QR code to view highlights from the Disposable Hygiene Products Machinery and Packing Machinery Pavilion

Ø Disposable Hygiene Products Machinery: Digital Intelligence Drives Efficiency, Flexible Packaging Meets Diverse Needs

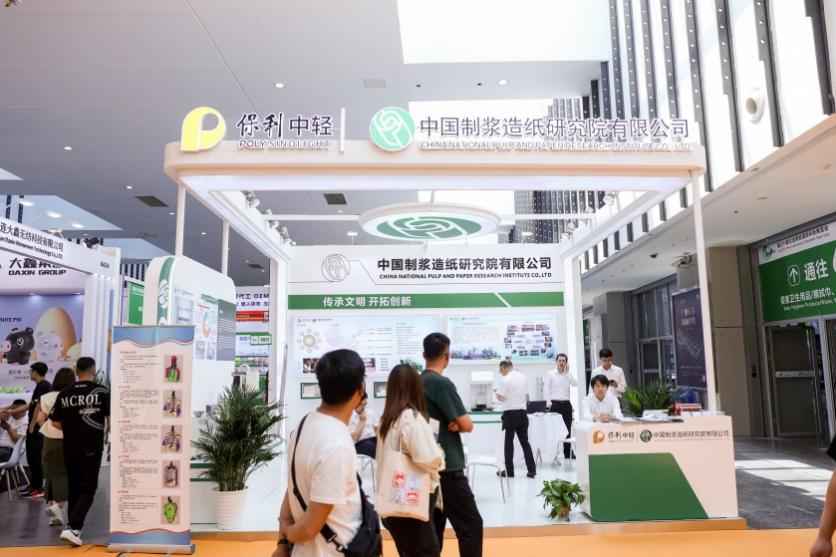

China National Pulp and Paper Research Institute Co., Ltd. (CNPPRI) exhibited related hygiene product testing equipment, such as the Diaper Absorbility Tester, supersonic spray coating rollers, wet strength agents, antibacterial and deodorizing agents, and Zhongqing (Jinjiang) Hygiene Products Testing Services, offering multi-faceted introductions and consultations for industry enterprises on-site. The Diaper Absorbility Tester, Water Absorption Tester, Lint Tester, and Dispersibility Tester are the latest hygiene product testing equipment under current standards, collectively supporting the high-quality development of the hygiene products industry.

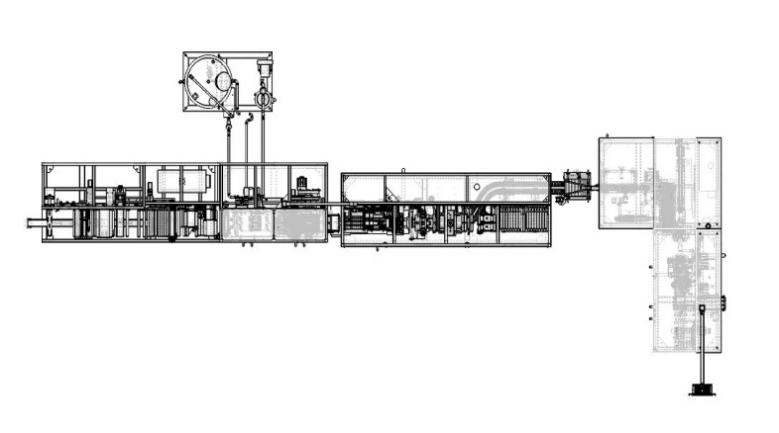

Anqing Heng Chang Machinery Co., Ltd. focused on exhibiting the 1,000 PPM baby training pants production line and the 500 PPM menstrual pants production line. These lines offer stable operating speeds, high efficiency, and a high degree of modularity and intelligence, capable of accommodating different packaging formats and single/double row packaging. All equipment is self-designed and manufactured, possessing complete independent intellectual property rights.

1,000 PPM Baby Training Pants Production Line

500 PPM Menstrual Pants Production Line

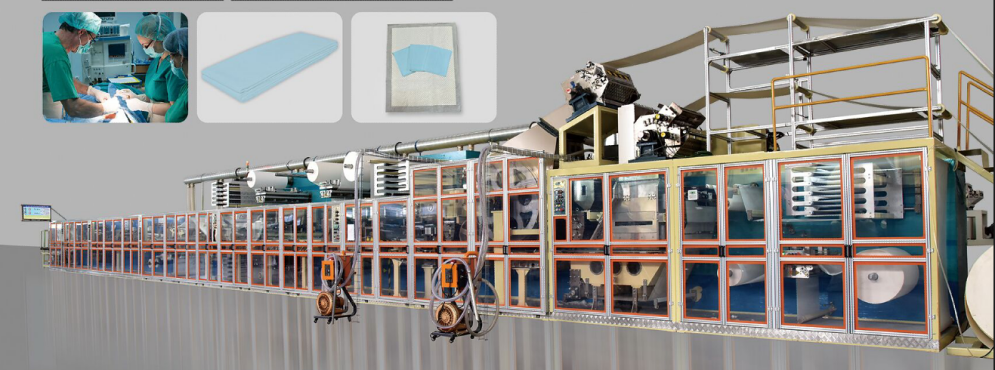

Jiangsu Jwc Machinery Co., Ltd. featured its Full Servo Ultra-High-Speed Under Pad (Pet Pad) Machine. This production line can meet the multi-specification co-line production needs for both 3-layer and 5-layer under pads, with a production speed reaching 350 m/min. Based on fluid dynamics design principles, it reasonably configures the pressure and airflow direction within the forming chamber, ensuring uniform forming and enhanced fiber cross-linking strength even at high operating speeds. The mold wheel station uses a connected extended mandrel, enabling quick size changeover in 30 seconds. The core hydraulic device ensures constant pressure and clear, uniform embossing at ultra-high speeds. The modular design allows for rapid assembly and startup of the equipment.

Full Servo Ultra-High-Speed Under Pad/Pet Pad Machine

Quanzhou Dachang Paper Machinery Manufacturer Co., Ltd. launched the DC-2020D Full-auto Wet Wipes Machine. The entire machine adopts bus-type PLC and full servo control, making positioning adjustments easy, accurate, and operation stable. The raw material rack is dual-unwind, featuring automatic web splicing and automatic film splicing. Equipped with a slitting mechanism, the master roll can run as a single roll or dual rolls in parallel. It uses immersion-type liquid addition with automatic replenishment when low, and a pneumatic water pressing mechanism for even water distribution. The conveying, cutting, and folding functions are handled by independent modular units, facilitating adjustment and ease of maintenance.

DC-2020D Full-auto Wet Wipes Machine

Quanzhou Zhigao Machine Co., Ltd. highlighted its compactly designed Full-Servo Under Pad Production Line, which is easy to operate and maintain. It employs a modular design, offering low energy consumption and high efficiency. It is equipped with an automatic edge guiding device and automatic quality detection sensors, stopping automatically if raw material breaks. The human-machine interface allows for automatic recording and calculation of production data.

Full-Servo Under Pad Production Line

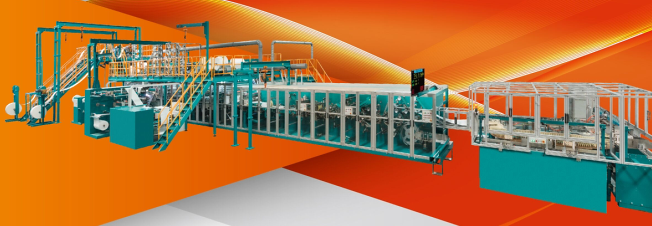

Zhejiang NEW YUHONG Intelligent Equipment Co., Ltd. prominently displayed the CSG-AD350 Full Servo Adult Diaper Production Line. This line can produce both tape-style and pant-style adult diapers, with convenient and quick one-touch size changeover, minimizing waste associated with changeovers. It is configured with a high-density ultra-thin absorbent core forming system and an automatic edge guiding device, enabling online production of ultra-thin cores. The equipment can be optionally equipped with zero-waste technology, a packaging machine, a palletizer, and a dust collection system, achieving modular production.

CSG-AD350 Full Servo Adult Diaper Production Line

Quanzhou Chuangda Machinery Manufacture Co., Ltd. focused on exhibiting the CD-600 High Speed Single Piece Wet Wipe Machine with Intermediate Packager. With a design speed of 400 pieces/min, it helps customers achieve higher-speed production with fully automated operation. The produced single-fold wipes are directly fed into intermediate bags for packaging. Equipped with a full servo control system, it can automatically adjust packaging paper length and perform color mark tracking, featuring non-stop automatic raw material splicing, which reduces downtime during material changes. The configured intermediate packager is highly automated and will not pick bags if no product is present, avoiding waste of outer packaging bags.

CD-600 High Speed Single Piece Wet Wipe Machine with Intermediate Packager

Zhengzhou ZLINK Machinery and Equipment Co., Ltd. highlighted the WE-MF2 Super-mini 3D Packing Wipes Production Line at this expo. The produced wipes have a fashionable and aesthetically pleasing appearance with a strong three-dimensional feel, are more hygienic compared to traditional semi-automatic sealing, and offer high speed. The conveyor belt for wipes is designed for easy removal, simplifying cleaning and disinfection. Electronic detection enables automatic control, stopping and alerting when liquid is low, and stopping liquid injection when full. The pipelines and liquid addition pump adhere to sanitary standards with non-retention and dead-angle-free 3D design, suitable for pasteurization and disinfectant rinsing.

WE-MF2 Super-mini 3D Packing Wipes Production Line

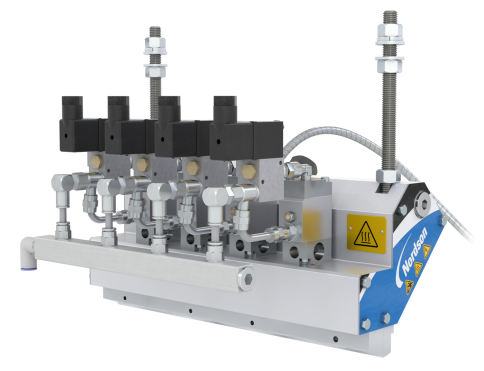

Nordson (China) Co., Ltd. launched the latest AltaCoat-i coating head. It supports medium-speed intermittent coating applications, adopts an embedded module design with high heat transfer efficiency, and is equipped with a high-speed retraction intermittent module that optimizes coverage and improves adhesive application accuracy. Its compact design facilitates maintenance.

AltaCoat-i Coating Head

Maxcess (Zhuhai) Industrial Automation Equipment Co., Ltd. highlighted its FIFE-500 MAX Web Guiding System. It features network communication capability, is configured with a 5-inch color touchscreen supporting multiple languages. An 8-pole motor enables smoother guiding, higher accuracy, and less waste. It offers high cost-effectiveness, reduces maintenance, and can quickly adapt to web variations even on high-speed production lines.

FIFE-500 MAX Web Guiding System

Ø Disposable Hygiene Products Packing Machinery–Flexible Changeover, Stable Performance, Cost Optimization

OPTIMA Packaging Machines (Shanghai) Co., Ltd. introduced its first model, the BDS-1, with some components localized for the baby diaper market in China. Further optimizations were made based on Chinese customer needs, including seal design and pusher head improvements. The feed speed is 500 pieces/min, the packaging speed is 45 bags/min, and it is compatible with both Chinese-style and European-style bags.

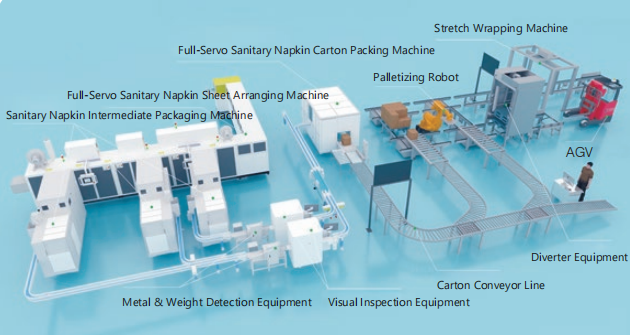

Xiamen Gachn Technology Co., Ltd. launched intelligent end-of-line packaging overall solutions for the entire category of home care and personal care products. Their product line can integrate with the user's factory MES system, providing a digital factory layout. The workflow for the full-category production line is as follows: Fully Automatic Stacking Machine → Fully Automatic Packaging Machine → Online Inkjet Printing → Online Checkweighing & Metal Detection → AI-based Intelligent Packaging Quality Inspection → Fully Automatic Cartoning Machine → Fully Automatic Palletizer → Automatic Stretch Wrapping Machine → Warehouse Storage.

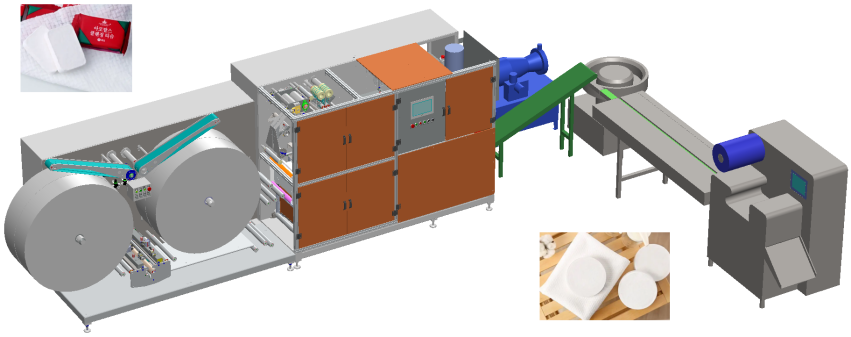

Xiamen ForePak Machinery Co., Ltd. featured the FP8900 Fully Automatic High-Speed Compressed Towel Production Line. This line achieves fully automated high-speed production of compressed towels, from cutting, folding, compressing, to packaging, eliminating human contact with the product for safety and hygiene. The equipment uses a hydraulic system to provide pressure, allowing real-time online adjustment of pressure and compression effect. It avoids the wear, difficult adjustment, and maintenance commonly found in mechanical cam mechanisms. The mechanical part adopts an integrated mold modular design with a simple mechanical structure, allowing quick mold and specification changes.

FP8900 Fully Automatic High-Speed Compressed Towel Production Line

Xiamen Hengdafeng Machinery Co., Ltd. highlighted its P26 Fully Automatic Packaging Machine for Adult Under Pads and Pet Pads. It features fully automatic sealing, is equipped with an automatic edge trim suction device, and uses Inovance PLC program control for accurate positioning, high precision, a high degree of automation, and simple operation.

P26 Fully Automatic Packaging Machine for Adult Under Pads and Pet Pads

电话:010-64778188

电话:010-64778188  Email:cidpex@cnppri.com

Email:cidpex@cnppri.com