REVIEW

CIDPEX ReviewRaw & Auxiliary Material Pavilion: Functional Innovation for Green and Sustainable Development

By Wang Juan

At this year’s China International Disposable Paper Expo (CIDPEX), nearly 300 raw and auxiliary material suppliers launched and promoted their annual new products and technologies, covering nonwovens, films, Super Absorbent Polymers (SAP), hot melt adhesives, packaging and printing materials, among others.

Raw and auxiliary materials are becoming increasingly specialized in function while their performance continuously improves. Examples include breathable yet waterproof nonwoven backsheets, soft and comfortable nonwovens, ultra-fine fibers, SAP designed for differentiated absorption needs, and hot melt adhesives offering stronger adhesion, lower application temperatures and reduced odor, all providing consumers with more choices. Moreover, raw and auxiliary materials are steadily advancing towards environmental sustainability. New materials such as biodegradable fibers, SAP, hook-and-loop fasteners, and packaging films are continuously emerging, laying the foundation for the industry’s sustainable upgrade. These new products and technologies directly drive the upgrading of tissue paper and hygiene products, leading industry development trends.

Scan the QR code to view highlights from the Raw & Auxiliary Material Pavilion

King’s Choice (Jiangsu) New Material Co., Ltd.

King’s Choice’s newly launched high-breathability, high-hydrostatic pressure breathable nonwoven can replace traditional PE films in diapers. Compared to commonly used PE films in the market, its leak-proof performance is improved by approximately 200%, while its breathability is enhanced by about 300 times, improving the consumer experience and delivering ultimate breathability during use.

Shanghai Fengge Nonwoven Co., Ltd.

Fengge’s new lint-free, dry and ultra-soft topsheet nonwoven is the result of collaborative development with the upstream and downstream partners. It features optimized fiber material properties and production processes, alongside upgrades to hot air equipment and thermal bonding processes. These improvements result in a softer, fluffier, smoother surface material with an enhanced skin feel. Upon liquid contact, the material contracts, allowing rapid penetration and minimal residue, thereby achieving a dry, lint-free, clean surface with excellent anti-rewet properties.

Xinjiang Zhongtai Henghui Medical Sanitary Materials Co., Ltd.

Zhongtai Henghui’s new ultra-soft spunlace nonwoven utilizes 100% cotton fiber, and features comprehensively upgraded performance: ultra-soft, skin-friendly, and highly absorbent. The material comes with specially designed patterns, including cotton blossom, pearl, EF, mesh, and plain weave. With diverse application scenarios, it can be used for dry wipes, wet wipes, face masks, and is suitable for sensitive groups such as infants, pregnant women, and individuals with sensitive skin.

Lenzing Fibers (Shanghai) Co., Ltd.

Lenzing prominently featured Veocel™ Lyocell fibers, certified as carbon neutral products by ClimatePartner. The production process utilizes renewable energy and incorporates reforestation projects for carbon removal, balancing unavoidable carbon emissions. This approach aligns with China’s dual carbon policy, helping companies meet their carbon reduction targets.

Veocel™ Lyocell Shortcut fibers, employing Eco Disperse technology, are designed for flushable moist toilet tissues. They disperse when flushed down the toilet and are biodegradable.

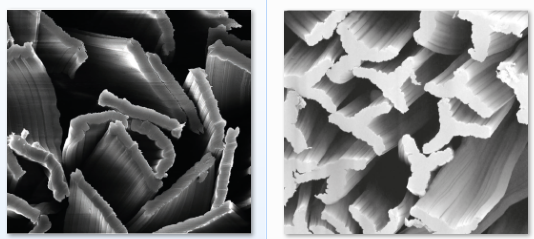

Kelheim Fibres GmbH from Germany

Kelheim Fibres are made from 100% natural cellulose, sourced from sustainably managed forests (PEFC, FSC, Canopy certifications), and are fully biodegradable in water and soil. It primarily showcased three specialty fibers: Galaxy fibers, VILOFT short cut fibers, and Microfine superfine fibers in this expo. Galaxy fibers feature a Y-shaped cross-section for superior moisture absorption, making it ideal for tampon products. VILOFT short cut fibers offer excellent flushability and can be customized for softness, absorbency, and strength. Microfine superfine fibers, with a fineness of 0.5D, provide exceptional softness to products.

VILOFT short cut fibers and Galaxy fibers

H. B. Fuller (China) Adhesives Ltd.

H.B. Fuller launched new high-performance hygiene adhesives, including the Full-Care 5190A series (low-temperature construction adhesive), the Full-Care 7080AZP series (hot melt adhesive suitable for bonding pure cotton materials), the Full-Care 8081AZP series (elastic adhesive with good creep resistance suitable for S curve application), and the Full-Care 6191AZP series (positioning adhesive that prevents oil bleeding).

Full-Care 5190A and Full-Care 6191AZP Hygiene Adhesives

Dongguan CO-MO Adhesives Co., Ltd.

CO-MO launched several products: the CM929MAU series hygiene adhesive, offering good low-temperature initial tack and excellent resistance to performance decay; the CM929IU series hygiene elastic adhesive, which is non-dripping on equipment, enables low application amounts, and provides excellent anti-creep performance; the CM929V10U series low-temperature hygiene construction adhesive, featuring fast melting and smooth application even at temperatures as low as 120°C; the CM929GU series low-temperature hygiene wet strength adhesive, delivering better wet peel strength than standard hygiene construction adhesives, preventing delamination in damp conditions; and the CM929V9AU series construction adhesive, which helps reduce product odor.

Henkel (China) Investment Co., Ltd

Henkel launched a new low-temperature elastic adhesive, with the following benefits:

For consumers: Lower odor for greater peace of mind; excellent anti-creep performance for more comfortable application experience.

For manufacturers: Low-temperature application suitable for thinner, finer substrates, reducing burn-through on nonwovens, backsheets, and elastics; good material compatibility and machine performance for various application processes; effectively helps save energy and reduce costs.

Yixing Danson Science and Technology Co., Ltd.

Danson highlighted its new DScom® series SAP for rapid blood absorption, the DSorb® OC series SAP for efficient and long-lasting antibacterial and deodorizing properties, and its high-quality traditional 228 series / 7 series / 8 series SAP.

Formosa Industries (Ningbo) Co., Ltd.

Formosa featured its Taisap low rewet series (BC8001) SAP, which offers good centrifuge retention capacity and absorption under pressure. Used in diapers, it provides long-term low rewet performance and can be widely applied in composite core baby diapers.

Chongqing Hetai Runjia Co., Ltd.

Hetai Runjia launched biodegradable films for sanitary napkin backsheets, small package films, and outer packaging for sanitary napkins and diapers. The material contains PLA and PBAT, is printable, and degrades by 90% into water and carbon dioxide under composting conditions, with the remaining 10% converting into inorganic salts and other components.

Binder Fasteners (Nanjing) Co., Ltd.

Binder showcased its new generation ultra-soft Binder Hook®, and biodegradable hook-and-loop fasteners. The new ultra-soft Binder Hook® (Microplast® Soft) offers special softness and toughness. The biodegradable hook-and-loop fasteners come in two variants: one primarily using polyolefins, the other using polylactic acid (PLA).

Tianjin SINOSH New Material Technology Co., Ltd.

SINOSH showcased its new antibacterial, deodorizing, and antioxidant cores, suitable for various products such as feminine hygiene items, adult incontinence products, and pet pads.

The product uses naturally fermented lactic acid as raw materials, ensuring high safety. It maintains a weak acidic environment for broad-spectrum antibacterial action, promotes a healthy micro-ecology, and neutralizes odors at the source. Combined with tea polyphenols, which are known for strong antioxidant capacity and physiological activity, it acts as a pure natural scavenger of free radicals in the human body.

Micro-emulsification technology tightly binds the functional ingredients to the material fibers, ensuring stable efficacy.

Process upgrades and diverse application forms allow for combining and layering product functionalities. Based on customer needs, the functional ingredients can be stably applied to air-through and spunlace nonwovens.

电话:010-64778188

电话:010-64778188  Email:cidpex@cnppri.com

Email:cidpex@cnppri.com